Sales of equipment

Selling new and used and also offering leasing of complete production lines, our clients are companies operating in the Oil & Gas, Mining, Steel, Industries, Pulp and Paper market among others.

Smart Welding is located in the municipality of Macaé-RJ, considered the National Capital of Brazilian Petroleum. We occupy an installation at Parque Lagomar with innovative technologies and intelligent solutions in welding and CNC processes.

We use state-of-the-art and precision technology, seeking to reduce execution time and guarantee efficiency in the application of resources and quality of services, being effective in our clients' results, reducing time losses and failure rates during project execution.

Our work processes serve companies from oil & gas (on / off-shore), shipbuilding, power, tube machining, power generators, piping lines to simple repair and maintenance services.

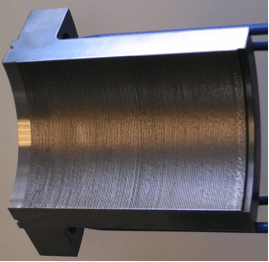

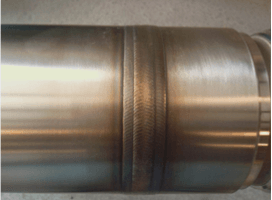

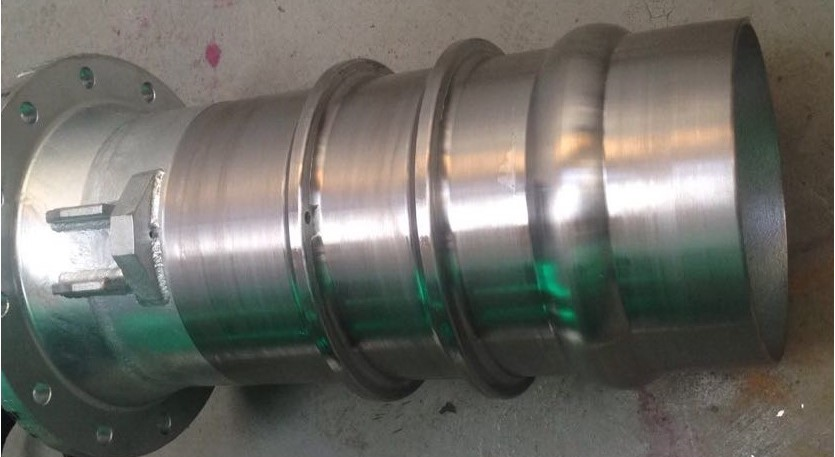

Refers to a process in which a metal, resistant to corrosion or composite (coating material) is electrically connected, or mechanically through some process of high pressure and temperature to another metal (the substrate) to increase its durability, resistance or appearance or just return to original dimensions and sealing. The cladding weld is usually between 2 and 20 mm thick. It can be applied using a variety of welding processes where SMART Welding is able to perform, including TIG (GTAW), Mig / Mag (GMAW), submerged arc (SAW) and plasma welding (PTAW) welding processes.

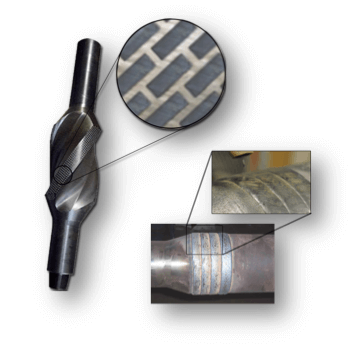

After repairs and successive cutouts, important drilling tools may not meet acceptable inspection standards, rendering them unfit. Following detailed procedures and techniques, stub-welding allows a "lost" material to return the tool and bring it back to the original specifications and make them fit for service again.

The result of significant savings in downtime and production costs has meant that this process has been adopted in a number of industries, including steel, cement, mining, petrochemicals, energy, sugar cane and food. Especially in the oil and gas sector are more common to fix redress stabilizer and hardbanding riser due to the need to stabilize BHA during drilling or reduce aggressive damage in tools. The process can be T2A flamespaving or PTA and brazing process (H300 and Cotraite).

Selling new and used and also offering leasing of complete production lines, our clients are companies operating in the Oil & Gas, Mining, Steel, Industries, Pulp and Paper market among others.

Leasing of equipment to complete production lines, our customers are companies operating in the Oil & Gas, mining, steel, industry, pulp and paper market among others.

"The ISO 9001 Certificate attests that our Quality management system is qualified in accordance with the best practices of the norm in question. Certificates issued by a third party certification body such as DNV GL, attest to our clients that we have implemented in our internal processes every routine necessary to comply with our obligations. Delivering much more robustness, confidence and quality in our contracts!"

Certificate ISO :2015 | 237325-2017-AQ-BRA-INMETROThe arc and the puddle are protected by shielding gas, usually argon, CO2 or a mixture of these. The choice of gas depends on the material to be welded.

gas flow supplied at high pressure through a central tube. In this way, the gas, usually argon, is ionized to create a plasma arc column with high energy and temperature.